Low-Cost, High-Impact Safety Upgrades Every Facility Can Implement

When we think of “facility upgrades,” we often imagine six-figure automation or robotic guards. But for small facilities, the biggest wins usually come from clarity, consistency, and a little bit of cleverness. In 2026, the gap between “expensive safety” and “effective safety” has closed. Low-Cost, High-Impact Safety Upgrades = Practical steps that improve safety, reduce incidents, and deliver quick ROI without overhauling operations.

Small and mid-sized facilities often operate with tight budgets and limited staff — yet they still face the same safety obligations as larger sites. The good news: not every safety improvement requires a major capital outlay. Thoughtful, prioritized upgrades can dramatically reduce risk, improve compliance, and lower downtime with modest investment and straightforward execution.

Here is how small facilities are leading the charge without breaking the bank.

1. The Visual “Nudge”

High-visibility floor tape and convex mirrors at every blind corner. It’s a $200 investment that prevents a $20,000 forklift collision.

2. The QR Code Revolution

We all have smartphones. One of the highest-impact, lowest-cost upgrades is replacing paper “Near Miss” forms with QR codes posted at workstations. When reporting a hazard is as easy as scanning a code and snapping a photo, your data—and your ability to prevent the next big accident—skyrockets.

3. Lighting

You can’t avoid what you can’t see. Upgrading to high-output LED task lighting in picking zones or assembly areas does more than save energy; it reduces eye strain and prevents the missteps that lead to trips and falls. Many LEDs now include integrated motion sensors, ensuring no one walks into a dark, hazardous zone.

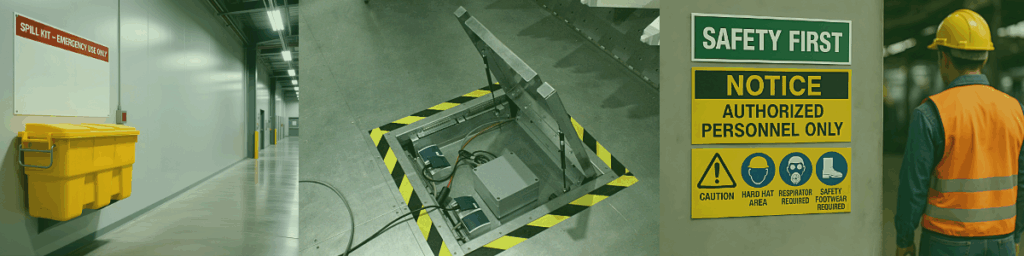

4. Standardize Visible, Actionable Signage

Clear signage reduces human error. Audit your facility for high-risk zones (chemical storage, machine rooms, confined spaces, stairwells) and install uniform, easy-to-read signs that state the hazard and required action. Signage is inexpensive, reinforces expectations visually, and supports faster, safer decisions when incidents occur.

- Replace faded or inconsistent signs with a standardized template.

- Add floor markings for traffic lanes and spill containment areas.

- Post simple emergency steps next to eyewash stations and exits.

5. Create Compact, Location-Specific Spill & Emergency Kits

Rather than one central supply closet, distribute small, application-specific kits where hazards are most likely to occur — battery charging stations, chemical mixing rooms, and maintenance bays. Localized kits cut response time, reduce contamination spread, and make it easier for on-shift staff to act decisively.

Kit ideas:

- Battery/Lithium incident kit: extinguisher, sand, thermal blanket, disposal container.

- Chemical splash kit: absorbents, neutralizer, PPE (gloves, goggles), small spill containment berm.

- Minor first-response kit: tourniquet, trauma dressing, gloves, compact rescue blanket.

6. Optimize PPE Storage and Readiness

Proper storage extends PPE life and improves compliance. When PPE is easy to access, clean, and clearly tracked, employees are more likely to use it correctly — reducing exposure and wear-related failures.

- Install wall racks for respirators and face shields with labeled hangers.

- Use clear bins for spare gloves and disposable suits with first-in/first-out rotation.

- Add simple checklist tags for reusable gear (date last inspected, next inspection due).

7. Implement Short, Role-Focused Micro-Training

Instead of lengthy annual sessions, roll out 15–20 minute micro-training modules tied to specific roles and seasonal risks. Short, frequent training increases retention, fits tight schedules, and can be tailored to immediate hazards.

8. Prioritize Low-Cost Instrument Checks & Documentation

Full calibration can be scheduled, but simple routine checks (bump tests, battery checks, visual inspections) should be non-negotiable. Create a weekly bump-test schedule for portable gas detectors with a shared log.

Putting It Together: A 30-Day Action Plan

- Week 1: Walk the site and document top 8 risk locations. Order signage and two types of kits.

- Week 2: Install PPE racks, deploy kits, and place QR codes on instruments.

- Week 3: Run the first wave of 15-minute micro-trainings and start the bump-test log.

- Week 4: Review results, collect feedback, and update the plan — schedule calibrations and deeper training as needed.

The “Small Facility” Safety Upgrade Checklist

Use this checklist to identify low-cost, high-impact safety Upgrades and quick wins during your next walk-through.

🛠️ Physical Environment (The Quick Fixes)

- [ ] Virtual Walkways: Are pedestrian paths clearly marked?

- [ ] Blind Spot Mitigation: Are convex mirrors installed at intersections?

- [ ] Shadow Boarding: Are tools organized on shadow boards?

- [ ] Anti-Fatigue Zones: Are mats placed where workers stand for extended periods?

- [ ] Clearance Check: Is there a 36-inch clear zone around electrical panels and exits?

📱 Digital & Communication (Modernizing)

- [ ] Instant Reporting: Are QR codes posted for hazard reporting?

- [ ] Digital LOTO: Do stations link to shutdown instructions?

- [ ] Live Alerts: Is there a shared safety alert communication channel?

🌬️ Health & Ergonomics

- [ ] Air Quality: Have HVAC filters been upgraded appropriately?

- [ ] Hydration Stations: Are water stations accessible to high-effort zones?

- [ ] Adjustable Heights: Can workstations be adjusted to operator height?

🧠 Training & Culture

- [ ] Fresh Eyes Audit: Has cross-department safety review been conducted?

- [ ] PPE Audit: Is PPE comfortable and consistently worn?

- [ ] Emergency Readiness: Can new employees quickly locate emergency equipment?

[Shop Safety Products Now] | [Contact Sales]