Comparing Gas Detection Solutions: Draeger X-am 5000 vs. X-am 5800

Comparing Gas Detection Solutions: Draeger X-am 5000 vs. X-am 5800. Here’s a breakdown to help you decide which device is right for you.

Choosing the Right Gas Detection Solution

When it comes to personal gas detection, reliability and performance are non-negotiable —especially in hazardous environments where worker safety depends on accurate readings and durable gear. Draeger has long been a leader in industrial safety solutions, and their latest evolution in multi-gas detection devices, the X-am 5800, builds on the solid foundation laid by the X-am 5000.

But what exactly sets them apart? Here’s a breakdown to help you decide which device best meets the needs of your team and your site.

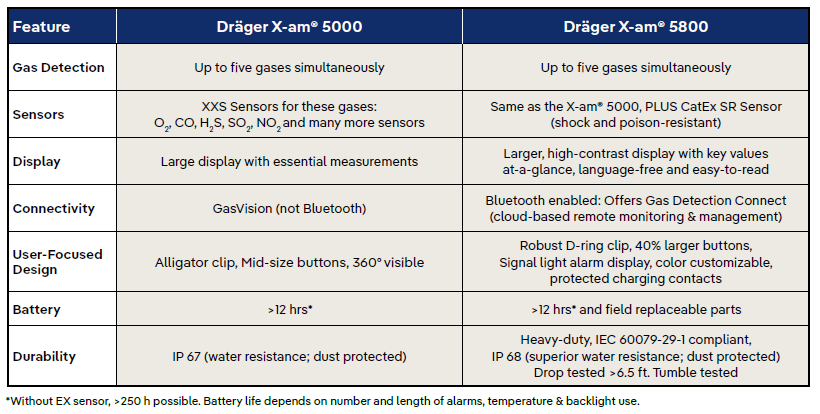

Core Functionality: Consistency in Detection

Both the X-am 5000 and 5800 are designed to detect up to five gases simultaneously, making them highly versatile for industrial applications. They use XXS sensors capable of detecting gases such as O₂, CO, H₂S, SO₂, and NO₂, among others.

However, the X-am 5800 includes an additional CatEx SR sensor that’s engineered to resist shock and poisoning. This sensor makes the 5800 a better fit for environments where catalytic sensors face performance challenges.

Environments where traditional catalytic bead sensors (CatEx) may not work reliably due to:

- Sensor Poisoning – Certain chemicals like silicone, lead, or sulfur can damage or deactivate a catalytic sensor permanently, even in small amounts.

- High Humidity or Moisture – Excessive moisture can affect the sensor’s accuracy.

- Low Oxygen Levels – Catalytic sensors need oxygen to work. In oxygen-deficient environments, they might underperform or give false readings.

- High Gas Concentrations – Overexposure can “saturate” the sensor and delay recovery or permanently reduce sensitivity.

- Mechanical Shock or Vibration – Traditional CatEx sensors are more fragile and may not hold up in high-impact or high-vibration settings.

Which is why, the CatEx SR sensor in the X-am 5800 is such a big deal! The 5800 is designed to be shock and poison-resistant. It performs more reliably in tough industrial conditions like refineries, tunnels, or confined spaces with unpredictable gas profiles.

Enhanced Usability: Smarter, Tougher, and More Intuitive

- Display: The X-am 5800 offers a larger, high-contrast screen with a language-free, easy-to-read interface. That means faster, clearer interpretation of data in stressful or low-visibility situations.

- Design & Ergonomics: The 5800 improves on the original alligator clip by adding a robust D-ring, and increases button size by 40%—a crucial detail for gloved users. It also features 360° signal lights, customizable colors, and protected charging contacts to streamline daily operations.

Connectivity & Remote Monitoring

While the X-am 5000 connects via GasVision software, the X-am 5800 steps into the future with Bluetooth capability, enabling cloud-based remote monitoring and device management through Draeger’s Gas Detection Connect platform. This is a game-changer for large sites and fleet management, allowing real-time updates and faster response times.

Durability & Maintenance

- Ingress Protection: The 5800 meets IP68 standards for superior water and dust resistance (vs. IP67 for the 5000).

- Drop & Tumble Testing: Built to endure tough conditions, the 5800 is both drop-tested to over 6.5 feet and tumble tested.

- Serviceability: The 5800 also features field-replaceable battery parts, making on-site maintenance faster and more cost-effective.

Which One Should You Choose?

Choose the X-am 5000 if:

- You’re in a lower-risk environment.

- Bluetooth connectivity isn’t a must.

- You want a cost-effective, dependable multi-gas monitor.

Upgrade to the X-am 5800 if:

- Your team works in rugged, high-risk conditions.

- You need real-time monitoring and cloud integration.

- You want the latest in user-friendly design and long-term serviceability.

The X-am 5800 represents a leap forward in personal gas detection; it’s designed for the realities of today’s industrial environments. If your worksite demands durability, connectivity, and clarity under pressure, this next-generation monitor is worth the upgrade.

If you’re interested in learning more view/download the datasheet or get in touch with our team today.